Repair / Rewinding

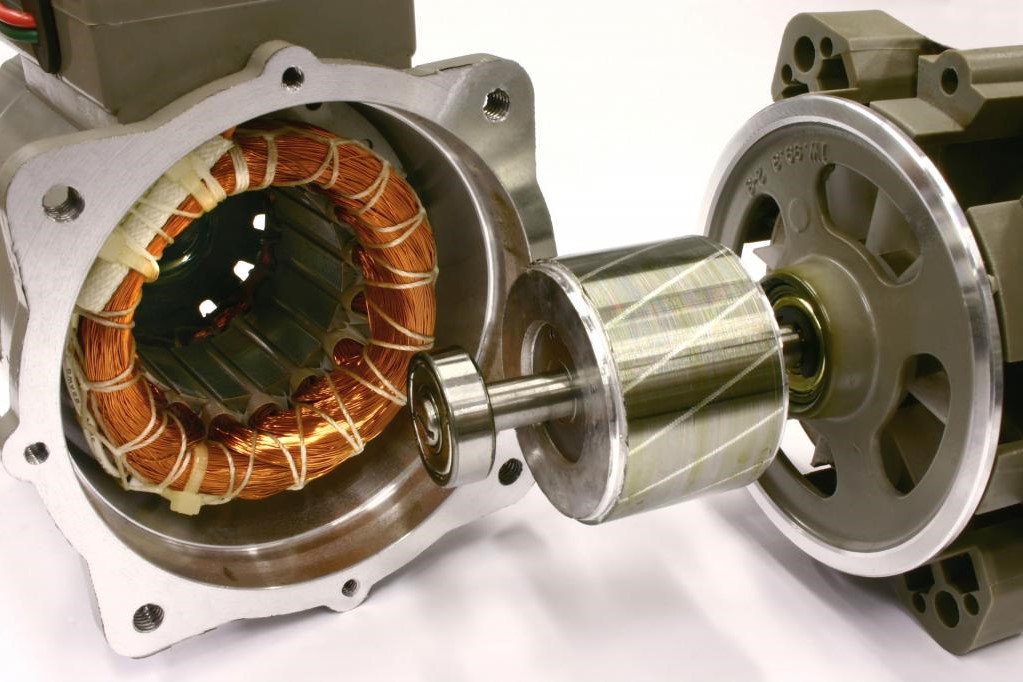

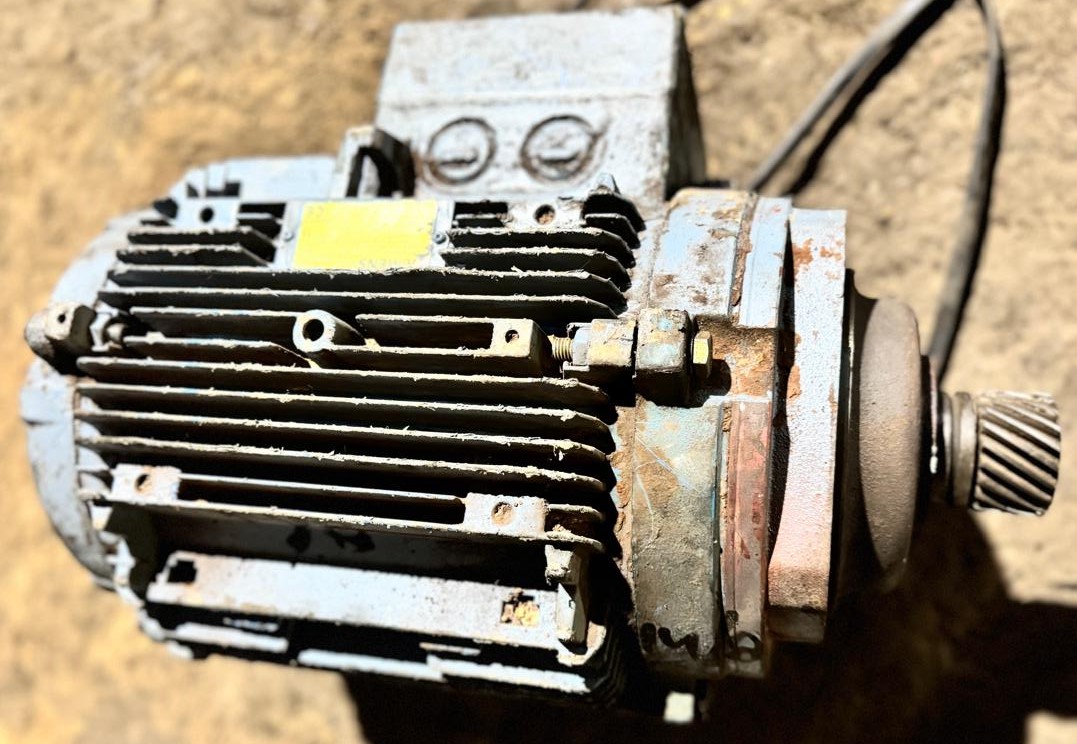

Rewinding/Repairing of

LT Motor

Professional rewinding services for A.C. motors up to 650KW, ensuring optimal performance and longevity.

Repair/Rewinding of

D.C. Motors up to 150 KW

Expert repair and rewinding services for D.C. motors up to 150 KW, ensuring optimal performance and reliability.

Rewinding & Repairing

of Transformer

Expert rewinding and repair services for transformers, ensuring optimal efficiency and reliable operation.

Repair/Rewinding of

3.3/6.6/11 KV HT Motors

Specialized repair and rewinding services for high-tension (HT) motors up to 11 KV, ensuring reliable operation.

Repair/Rewinding of

All Types of Alternators

Expert repair and rewinding services for all types of alternators, ensuring reliable power generation.

Rewinding of Submersible

& Monoblock Pump Motor

Rewinding of submersible and monoblock pump motors to restore efficiency, performance, and extend operational life.

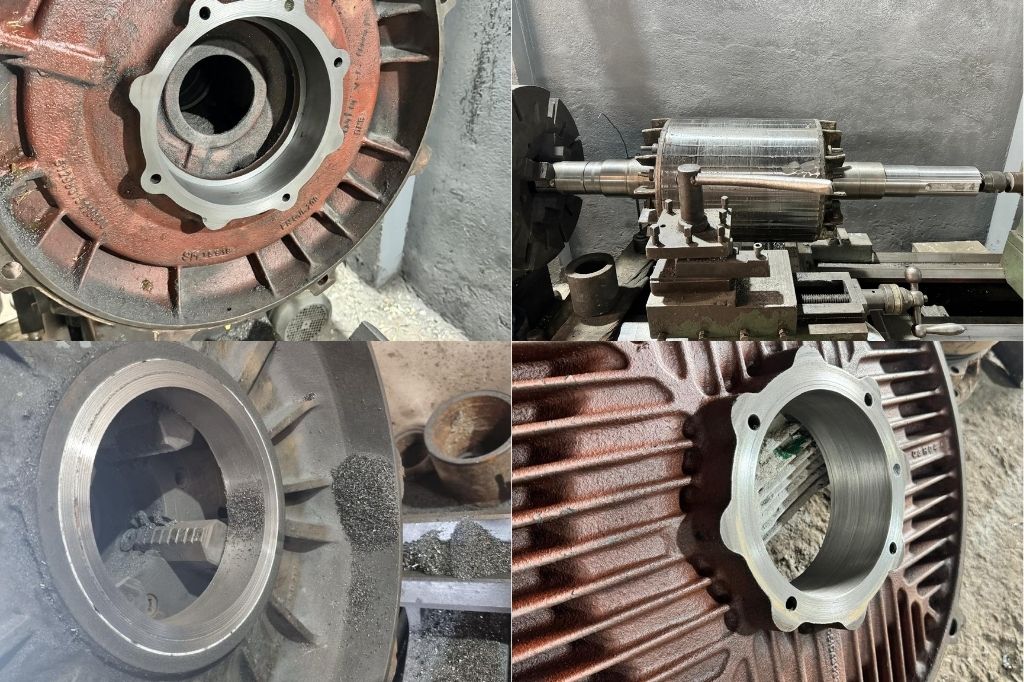

Rotor and Shaft Repairs

Cryogenic Cleaning (CO2)

of Stator & Rotor Facility

CO2 cryogenic cleaning of stator and rotor to enhance performance, efficiency, and extend motor lifespan.

Change of Shaft of All

Types of Electric Rotors

Efficient shaft replacement services for all types of electric rotors, ensuring optimal functionality and performance.

Fabrication of Rotor Shaft

of A.C./D.C. Motors

Precision rotor shaft fabrication for A.C. and D.C. motors, ensuring winding protection

and reliable performance.

Worn out Bearing Seat

and Shaft Repair

Precision repair of worn-out bearing seats and shafts, restoring durability and performance.

Mechanical Repairs & Fabrication

End Shield Cover Bearing

Housing Bush Fixing &

Rotor Shaft

Replacement

Work

End shield bush fixing and rotor shaft replacement to restore motor performance.

END SHIELD COVER AND

COOLING FAN CASTING /

FABRICATION

End shield repair and fabrication of motor/alternator cooling fans for improved cooling and performance.

Soft Foot and New Motor

Mounting Foot Fabrication

Work

Soft foot correction and fabrication of new motor mounting feet for improved alignment and stability.

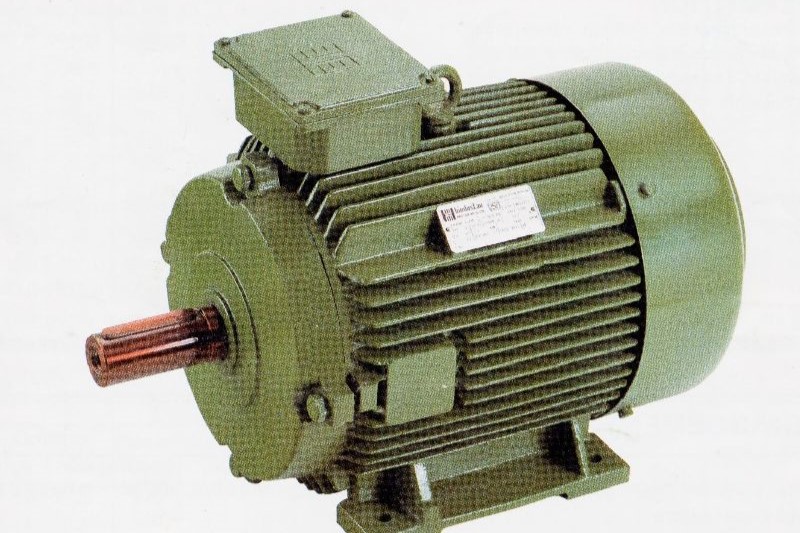

Crane Duty / Flame Proof

Motors

Crane duty and flame-proof motors designed for heavy-duty applications, ensuring safety and reliable performance in challenging environments.

Dynamic Balancing

Dynamic Balancing of

Rotating Component up to

5

Ton

Dynamic balancing of rotating components up to 5 tons, ensuring smooth operation and minimizing wear.

Testing and Electrical Services

DC Welding Generator

Comprehensive repair and maintenance of DC welding generators, ensuring consistent power output,long-lasting reliability for welding applications.

Rewinding of Electro

Magnets

Expert rewinding of electro-magnets to restore their magnetic properties, improve performance,ensure long-term reliability in various applications.

New Fabrication/Repair of

Slipring Assembly and

Brush Holder

New fabrication and repair of slip ring assembly and brush holder to ensure smooth operation and optimal performance.

Converting Aluminium Die

Cast Rotor to Copper Bar

Rotors

Conversion of aluminium die-cast rotors to copper bar rotors for improved conductivity and enhanced motor efficiency.

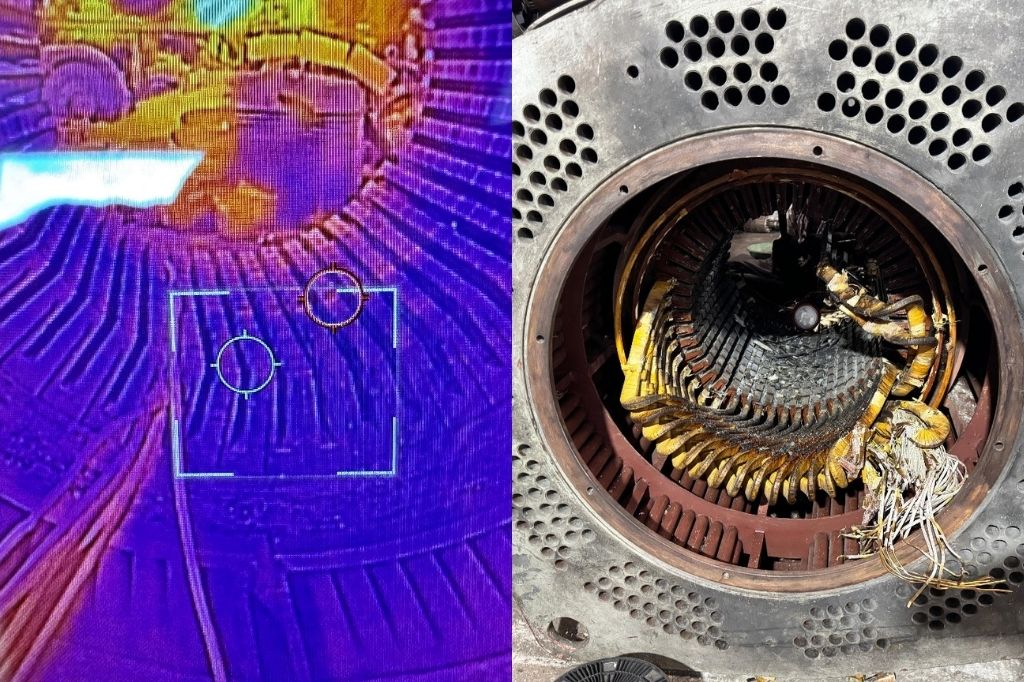

Removal of Core Hot Spot

and Core Staggering of LT

Motors

Removal of core hot spots and core staggering in LT motors, improving performance and reducing energy loss.

Loading and Transportation

Loading and Unloading

Facility

Reliable and secure loading and unloading services for heavy equipment with ease and efficiency.

Two Nos. Service Vehicles

for Transportation

Logistics

Two dedicated service vehicles available for transportation logistics, ensuring timely and secure delivery of goods.

Maintenance and Servicing

LT & HT Motor Servicing

and Preventive

Maintenance

Comprehensive LT and HT motor servicing and preventive maintenance to ensure optimal performance and prevent unexpected failures.

HT Motor Lead Repair and

Replacement Work,

Magnetic

Wedge

Replacement

Repair and replacement of HT motor leads and magnetic wedges for improved much efficiency.

Motor Testing Facility

IR Value Testing 500Volt

to 10KVA

Accurate IR value testing from 500V to 10kV, ensuring reliable insulation and optimal performance assessment.

Resistance Testing

Comprehensive resistance testing services to ensure accurate measurements, reliable performance, and equipment efficiency.

Inductions Testing

Comprehensive induction testing services to assess equipment performance, ensure

reliability, and optimize operational efficiency.

P.I. Value Testing

Comprehensive P.I. (Polarization Index) value testing to assess insulation condition and ensure long-term reliability and performance.

Surge Comparison Testing

Surge comparison testing to evaluate insulation strength, detect weaknesses, and ensure the reliability of electrical systems.

Hot Spot Testing

Hot spot testing to identify temperature irregularities, prevent overheating, and ensure the safe operation of electrical equipment.

H.V. Testing

H.V. (High Voltage) testing to assess insulation strength, ensure safety, and verify the reliability of electrical systems under stress.

THERMAL IMAGING

Thermal imaging to detect temperature variations, identify issues, and ensure the efficient, safe operation of electrical systems.

No Load Trial Testing

No Load Trial Testing of L.T./H.T. motors at rated RPM and voltages of 11kV, 6.6kV, or 3.3kV to verify performance, efficiency, and operational reliability.

Dynamic Balancing

Dynamic balancing to ensure smooth operation, reduce vibration, and enhance the performance and lifespan of rotating machinery.

All Routing Testing

Comprehensive all routing testing to ensure the functionality, reliability, and optimal performance of electrical circuits and systems.

TAN Delta Testing

TAN Delta testing to assess the insulation properties of electrical equipment, detect potential faults, and ensure long-term reliability and safety.

Other Special Services

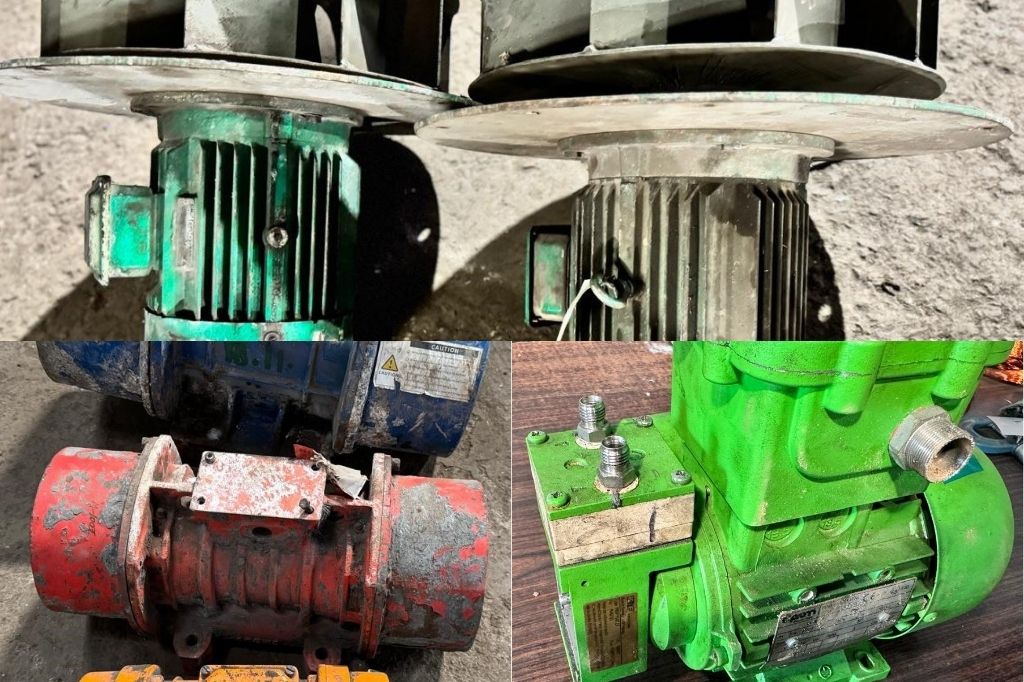

Vibrator Motors, Blower

Fan Motors & VFD Motors

Servicing and repair of vibrator, blower fan, and VFD motors for reliable and optimal performance.

Multi-Speed Motors

Repair and maintenance of multi-speed motors to ensure smooth transitions and reliable performance across speeds.

Inductor & Furnace Coils

Rewinding & Repairing

Rewinding and repairing of inductor and furnace coils to restore efficiency and ensure reliable operation.